Tech

Wire – A fine thing

Wire is a very critical part of each pickup when it comes to the frequency response, the production consistency of each model, and, of course, the final quality of the pickup. At GAS lab, we use the best available wire for repairing or manufacturing, provided by worldwide leaders in coil wire supply, such as MWS, Elektrisola, and Scientific Wire Ltd. Polysol coated wire P155 (AWG 42 and 43), plain enamel (AWG 42), and heavy PVA (AWG 42) are some of the finest wire sorts that we use.

Learn More

High-quality wire is essential for a pickup’s quality. The copper wire used on guitar pickup coils is of a very small diameter, mostly between 50μm and 63μm. The diameter is indicated according to the American Wire Gauge (AWG) system. It ranges from AWG 42 (63μm) to AWG 44 (50μm). The consistency of the wire’s diameter across its length is an important quality factor. Some companies (like Elektrisola) cover the outer wire surface with an ultra-thin layer of tin in order to keep the diameter as constant as possible.

A crucial thing is the insulation of the wire. There are many types of such insulation available, from ultra-thin plain enamel up to thick, heavy PVA (grade 2). The insulation thickness is more important than the insulation material itself because it determines how far the coil windings are from each other (called the winding density). This winding density will define coil values as the capacitance and the inductance, and therefore the overall frequency response spectrum of the pickup. With the same number of windings, a coil with wire of thicker insulation will show a wider frequency spectrum than the same coil with wire of thinner insulation.

A further factor that determines the winding density is the tightness of the winding procedure. More-tight winding leads to a denser-wound coil than less tight winding, and this also affects the final sound. By identical number of turns, tighter wound coils show a more midrange enhanced tone, than loose wound coils which show a more open tone. Coil air slots, which also re-define the frequency response, are also used at GAS lab.

Last but not least, the winding placement (distribution of the winds over the coil length) also defines the coil consistency and, thus, the consistency of the pickup. In order to provide the highest consistency between pickups of the same model, we use homogeneous winding, which means that all wire turns are precisely placed one next to the other without any gaps between them. However, in order to achieve different tonal characteristics, we use different winding profiles in our models, like parallel, oval, and triangle.

Base, roof and in-between

Metal parts used in humbuckers, like baseplates and covers can be really disastrous for the sound, since these may significantly increase eddy currents and thus decrease the frequency response curve of the pickup, especially in the midrange and treble areas. The effect appears mostly (but not only) on cheap pickups. Further metal parts are made of HQ steel alloys.

Metal pickup parts such as covers (which are found in Telly neck and humbucker pickups), base plates, pole screws, and slugs (mostly found in humbuckers and P-90 pickups) will affect the overall guitar tone as shaped by the pickup. Due to the parasitic eddy currents found on the surface of such parts, the midrange and higher frequency ranges will be mostly affected.

For that reason, at GAS lab we use high-quality metal parts mostly made of "bad" electric conductor material (as German silver), which will cause the least possible current leakage and therefore the least high-frequency damping.

The metal cover of a humbucker is one of the most important sound-affecting parts on a pickup. Cheap covers, usually made of brass (chrome or gold covered), show a tremendous cut of the high frequencies due to the high content of copper (which is a very good electric conductor). German silver-made covers are of much better quality since they are made of a material with a lot higher specific electric resistance, which does not allow but weak eddy currents to show on its surface. However, German silver covers that are chrome or gold plated show a different high-frequency response (with more damped resonance curved and lower resonance frequency value) than raw, un-plated ones.

This is a fact that should be considered, especially when ordering a humbucker. Most of the users decide whether to buy a cover or not, following strictly cosmetic criteria (how it looks better). Covered or uncovered, however, may have a significant impact on the upper midrange and highs, as explained above.

Technical specs of a pickup

After final assembly, each pickup will be controlled for its overall performance, the main part of which is the frequency response. But what are the main electronic values that describe a pickup’s performance? And how are these measured and confirmed? Does the widely mentioned DC resistance (the kOhms value) really tell anything about the pickup’s final frequency response and output level?

Learn More

At first glance, a magnetic guitar pickup is a very simple, primitive device. It consists mainly of one or more coils, permanent magnetic, non-permanent magnetic, and paramagnetic (non-magnetic) parts, such as the magnet bar (or rod), the pole screws, and the plastic bobbin (as respective examples). The pickup is a mechanic-electric transducer since it "translates" the string vibration into an electrical signal which changes through time by following a similar frequency pattern. This audio signal has the same root frequency of the string note that is being played (example an A at 220Hz), but a different harmonic content (frequencies that are mulitples of the root frequency, and cause the overall tonal characteristics of an instrument - the so called "timbre"). However, this is a very complex process. In the case of deep scientific analysis, this function cannot be easily described with a certain, generally used mathematical equation, a fact that certainly incommodes the proper design of a pickup. There are many reasons for that (such as imperfections in string vibration, inhomogeneity of the pickup’s magnetic material, and boundary conditions in the pickup’s surrounding areas, just to name a few), so we won’t go deeper here.

A way to describe the pickup functionality is to separate the whole process into a magnetic and an electrical part.

The magnetic part takes place right between the string and the pickup’s neighborhood and assigns the string vibration, which is a periodic (regularly changing in time) effect, to a respective periodic change of a magnetic value called the magnetic flux density.

This periodic change of the magnetic flux density induces an electrical current (the audio signal that is described above) through the pickup coil(s), and that's where the electric part of the pickup takes over. This current represents the sound of the string vibration and, hence, of the guitar itself. However, the pickup coil (as well as other metal parts on the pickup) acts as a filter for this primary signal, and it shapes the overall frequency spectrum. That's why it was mentioned before that the harmonic content of the electric audio signal is different than the harmonic content of the vibrating string. In a way, the guitar pickup is a microphone and a filter at the same time. And probably to great disappointment for those who believe it, a pickup is certainly not a sound generator; that’s why the same pickup will result in a totally different sound when put on a different guitar.

The overall frequency spectrum of the pickup is therefore a crucial characteristic because it will describe the expected effect of the pickup on the overall guitar tone. The spectrum is visually described by an x-y plot curve, which is called the frequency response (fr) curve. This curve shows how each pickup affects the whole frequency spectrum: Some frequencies are boosted, some are cut, others remain unaffected.

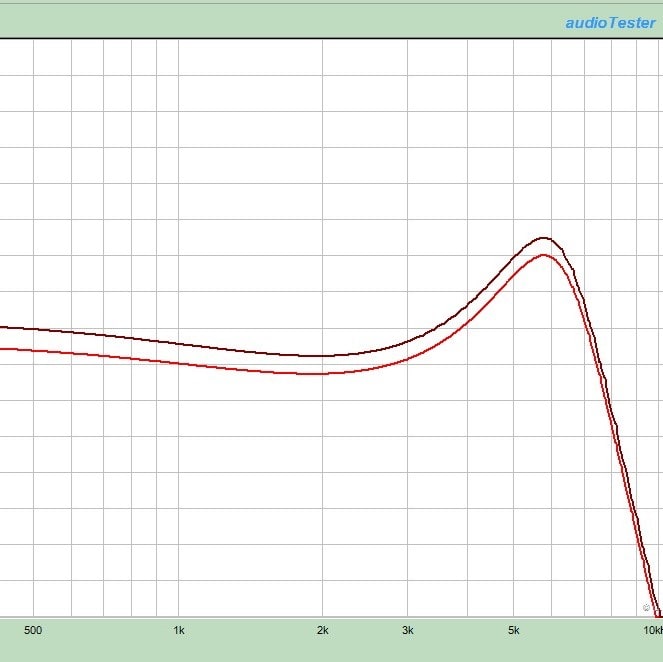

In order to better understand this, a typical such curve for a single coil pickup is shown above. The fr curve shows the enhancement or decrement of the pickup’s primary signal at each frequency inside a specific range. This range is usually set between 50 Hz and 12–13 kHz, which more or less corresponds to the audible range of the human ear.

Looking at the curve above, in the very low and low midrange frequencies, nothing happens; we have a more or less 1:1 signal transition. Depending on the pickup’s design, the midrange-high midrange range is where it starts to become interesting. There is always a bell-like curve formed (boost range), after which the signal level falls rapidly to non-audible levels (cut range). The highest point is the resonance frequency of the pickup, fres. The width of the bell curve (pointed at the 3 dB bandwidth) indicates the harmonic content of the resulted tone. The height of the resonance curve (resonance peak) also indicates how much the sound will be colored

The resonance frequency (Hz–kHz), the 3 dB bandwidth (Hz), and the resonance peak height (dB) are mainly dependent on the form of the pickup coil(s) and further metal parts found on a pickup (mostly on humbuckers and P90s), and less on the DC resistance (kOhms). Tone-wise, these values are the most important characteristic of a pickup since they tell us a lot about the range where the frequencies of the guitar signal are colored mostly. The assumption that "the higher the Rdc, the higher the output" is only valid if ALL other specs of the pickups to compare are identical (wire diameter, wire insulation, coil size, metal part alloy, magnet material, hookup wire, etc.), a fact that for regular users is very difficult to verify. As an example, we have the GAStation and the GAShopper, with 10 kOhms and 12 kOhms Rdc, respectively. The GAStation definitely has a higher output than the GAShopper. The reason here is the difference in the diameter (AWG) of the wire used on each model.

Therefore, from the facts that are described above, please keep the following in mind: When comparing pickup data, we strongly recommend not judging a guitar pickup by its DC resistance. Furthermore, it's the frequency response curve (frequency vs. level) and especially the resonance frequency of each pickup model that better describe the frequency response and harmonic content, which will determine the overall sound. You may find the resonance frequency in the specs section of each of our pickups.

Apart from this, there are other important factors that will further degrade the pickup’s frequency spectrum by lowering the peak and the value of the resonance frequency. These are:

Metal parts (as mentioned, found mostly in humbuckers and P90s): if you like more detail on this, please read here

The connection wire (a.k.a. "hook-up cable") of a humbucker and a P90-style pickup. GAS buckers and G models are fine-tuned during final quality control by the length of their connection wire (single braided or 4-conductor). Therefore, we recommend not shortening the wire in any way when installing a GAS humbucker or G model on a guitar.

The guitar electrics (volume and tone pots, tone caps, and the internal guitar wiring) The pots are used to mainly reduce the resonance peak and result in a more flat curve. That’s why singles, who show a higher (10dB range) peak, usually match with 250k pots, whereas humbuckers, who show a lower peak (5dB range) due to material-caused losses, usually match with 500k pots. However, this is not a rule. The user decides on the final sound

The guitar cable that is used. The part that connects the guitar to the next rig stage (pedalboard or amp) will drift the resonance frequency to lower values due to its considerable length (a few meters at least). Therefore, this cable must be considered a permanent part of the guitar (like the strings, pickups, etc.). We strongly recommend using the same cable for the same guitar.

Last but not least, a typical 12" guitar loudspeaker carries frequencies up to 6-7 kHz, a fact that also must be considered.

The resonance frequency, as for example given for every GAS model, is measured on the same device (the Lemme Pickup Analyzer), with no additional load of any volume or tone pot, except an 1 MegOhm resistance load (which represents a typical value for an input of a guitar amp) and no further added cable, just the hookup wire of the pickup itself. This allows an easy, valid comparison between different models, but ensures also the consistency of our pickup models.

Magnetic material

The most important parts of a pickup are its magnets. The magnetic material determines the dynamics at the first line and the frequency response in terms of the resonance-peak damping. At GAS lab, we use the finest magnetic material for all our products, which comes from world-known manufacturers such as Thomas & Skinner, AMT, Adams, etc. (US), Eclipse Magnetics (UK) and others.

Learn More

The main magnetic material categories that we use at GAS lab are Al-Ni-Co and ceramic magnets. Both have clear differences from each other and will behave differently on the same pickup in terms of dynamics and frequency response.

Al-Ni-Co material is an iron (Fe) alloy that contains aluminum (Al), nickel (Ni), and cobalt (Co) in considerable percentages, as well as copper (Cu) and titanium (Ti) in very small percentages (0–2%).

Depending on the Al-Ni-Co distribution inside the alloy, there are many Al-Ni-Co types (A-types), marked with a digit, such as A2, A3, A5, A8, etc. Each type of Al-Ni-Co alloy has different magnetic and electrical characteristics. Depending on their crystal structure and magnetization process, they may show different dynamic behavior and signal levels over the frequency spectrum, and since Al-Ni-Co alloys are electric conductors, they affect the midrange and higher frequencies. All these result in a different tone.

However, it is not possible to describe a certain alloy type (e.g., A5) with a specific tone or dynamic behavior. There are many reasons for this fact.

A first reason is that there is not only ONE A5 alloy composition, but, depending on the specific contain percentage of Al, Ni, and Co, there are over 7 different officially normalized A5 sub-alloys, such as A5-c, A5-7, A5-ab, etc. All these sub alloys show different tonal and dynamic range characteristics.

A further reason is that Al-Ni-Co alloys can be produced only in an industrial environment, following specific steps such as high heating, casting, magnetizing, cooling at a specific rate (Temperature downgrade per-minute rate), and many others (no need to go deeper in here).

Each manufacturer follows its own steps, so the same suballoy from two different manufacturers will probably have different tonal behavior on the same pickup. For example, there are currently five different A5 magnetic bars that we use in GAS humbuckers, from different manufacturers, and they all sound differently to each other (some show more bass, while others show more compression in the higher frequencies or more bite in the high midrange, etc.). So, there is actually no "A5 tone" or "A2 tone".

For all the above reasons, at GAS lab, we take care and deeply analyze the magnetic material that we intend to use in our products. By cooperating with the Institute of Nanotechnology at the Greek Nuclear Research Center "Democritus," we have analyzed many of our (currently used) magnet bars as well as a few old ones, such as two long bars from a 1959 P90 and a long bar from an early 1960 PAF. We found out that A5 bars from the end 50's used a different alloy composition, containing way more aluminum than the normalized A5 alloy compositions on the 1964 MMPA standards. And that's how we ordered some of our magnet bars.

The magnetic parts that we use for GAS Handmade Pickups®, especially in humbuckers and P90s, really make the difference in terms of tone and dynamic range.

We spent quite some time on research for this material. By contacting worldwide established magnetic manufacturers, we had the opportunity to try and analyze magnetic material from all of them.

Currently we use following bars on our humbuckers & G90's models:

- 2,500" long rough cast AlNiCo II (A2) - 1958 specs

- 2,500" long rough cast AlNiCo V (A5) - pre 1964 MMPA specs

- 2,500" long rough cast AlNiCo V-ab (A5) - 1964 MMPA specs

- 2,444" rough cast AlNiCo V-7 (A5) - 1964 MMPA specs

- 2,444" polished cast AlNiCo V-c (A5) - 1964 MMPA specs

- 2,370" "short" rough cast AlNiCo V-c (A5) - 1964 MMPA specs

- 2,600" Ceramic OX bars.

All the Al-Ni-Co bars that are listed above are made from the correct alloys and have different magnetization levels depending on the model used.

In more detail:

• The "long" 2,5" rough-cast A5 (pre 1964 MMPA specs) magnet bars, which are installed on some of our top-line Legend series pickups (such as the '59 PE, the '59 PVA and the '59 Green), come from the US manufacturer Thomas & Skinner, who was a supplier of top US musical instrument brands in the era of the 50's and 60's. These bars are exclusively made for GAS Pickups following an alloy composition as of the end of 50's (that’s before the MMPA standards of 1964 were applied). Therefore, these bars feature the same alloy composition as back then and are also degaussed (lower magnetized) for more dynamics. T&S bars provide our 59 Legend PAFoid models with the well known open tone and the required sensitivity and dynamic range.

• Further "long" 2,5" rough cast A5 bars, which are used on our 59 Legends, come from Eclipse Magnetics company (Sheffield/UK). These also built on old MMPA specs (low magnetization) and offer a warmer timbre, combined with high sensitivity, which makes them perfect for brighter guitars.

• The 2,5" long rough cast A5 bars that we use on our '58 Legends and the KF Signature set comealso from UK manufacturer Eclipse Magnetics. These are fully magnetized, and also offer a great sensitivity, but with a more enhanced low midrange and bass boost, which fits perfectly to the needs of a more aggressive, overwound set like our Legend '58ers or the KF set.

• 2,500" rough-cast A2 magnet bars are used on GASholder humbucker, but also on our '57 Legend and Night Train Legend sets.

• 2,444" A5 rough cast bars (A5-7 sub-alloy), based on the MMPA 1964 standards, are used on our 60 Legends

• 2,37" A5 rough cast bars which our TTop Legend models also come from Eclipse Magnetics.

• Our regular 2,444" polished A5 (A5-c sub-alloy) magnet bars, also based on the 1964 MMPA standards, are used on our A5 humbuckers of the standard series.

Of course, we are always in search of better material, so the above specs may change at any time.

Ceramic magnets are made of a totally different material than AlNiCo alloys. OX ceramic ferrites are electric isolators (they don’t affect the frequency spectrum of a pickup in any way), and they show different compression behavior (e.g., more tight bass). We use such material on some of our high-gain humbuckers (Flaming GAS, GASer Plus A, GAS Drax Custom Signature, etc.).

The dynamic behavior of a pickup depends directly on its magnetic material. Since it's a very complex procedure, we'll try to explain it very briefly.

As described in the chapter about the main features of a pickup, the string vibration causes a relevant change in the magnetic flux density B. The magnetic flux density causes a change in the magnetic field strength H inside the magnetic material. The magnetic field strength causes the electric current, which is then led to the pickup's output wires (the guitar's signal).

However, the ratio of these two values, B and H, which is called the magnetic permeability μ, is not constant, neither spatially along the magnet (bar or rod) nor through the frequency spectrum. In some frequencies, small changes in B (which means a light string pluck) cause a larger H value and thus a stronger current. This means that at these frequencies, the pickup shows greater sensitivity (a wider dynamic range). At other frequencies, even large B changes (which mean a stronger string pluck) cause very small H changes (a weaker current). At those frequencies, the pickup shows a more compressed signal.

The general behavior of each magnetic material in the dynamic range is therefore dependent on several parameters such as its construction, dimensions (short bar or long bar), production procedure (casting temperature, cooling rate), crystal structure, etc., and not only on its plain alloy composition. There are A5 bars that show a totally different dynamic behavior than other A5 bars from the same magnet manufacturer. Therefore, it's a highly important issue for a pickup designer to know and understand the dynamic behavior of the magnetic materials that are used in his products.